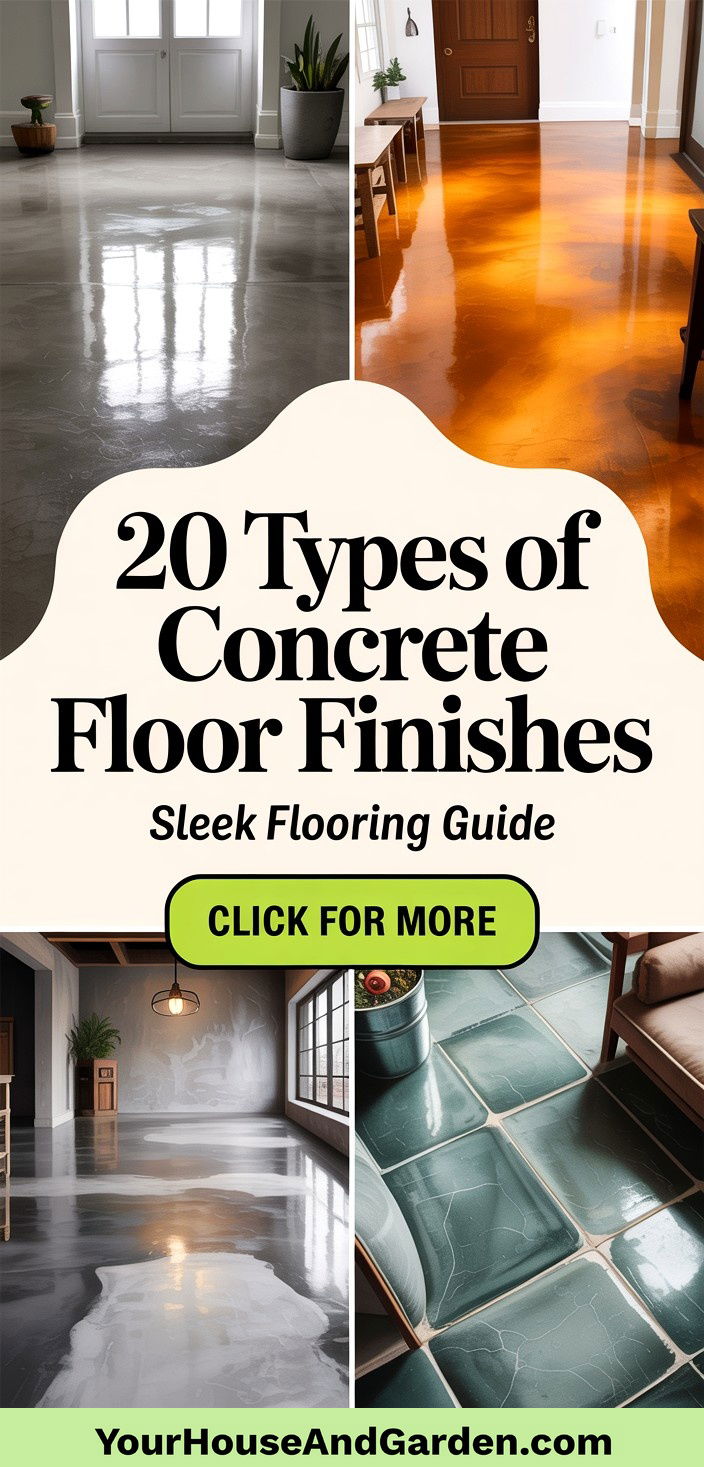

Concrete floors offer a versatile, durable, and aesthetically pleasing foundation for residential, commercial, and industrial spaces. With advances in materials and techniques, there are now numerous finishing options to enhance concrete’s natural qualities or transform its appearance entirely. From basic texturing for slip resistance to intricate overlays that mimic high-end materials, each finish serves specific functional and design needs. This article explores 20 distinct concrete floor finishes, providing insights into their processes, benefits, and ideal applications. Whether you seek a polished showroom floor, a rugged warehouse surface, or a decorative patio, understanding these finishes will help you select the perfect treatment for your concrete slab.

1. Trowel Finish

A trowel finish is one of the most basic and widely used concrete treatments, achieved immediately after screeding by using a steel or magnesium trowel to compact and smooth the surface. This method produces a dense, hard finish suitable for interior applications such as garages, basements, and commercial areas where a smooth, clean look is desired. While cost-effective and relatively quick to install, trowel-finished floors can become slippery when wet and often require additional sealing or coatings for improved traction and durability.

2. Broom Finish

The broom finish involves dragging a stiff-bristled broom across the concrete surface after the initial screeding and floating stages. This creates fine ridges that enhance traction, making it ideal for outdoor applications like driveways, sidewalks, and pool decks where slip resistance is crucial. Broom finishes are low-cost and straightforward to apply but result in a more utilitarian appearance. The texture can be adjusted by varying broom types and stroke techniques to achieve shallower or deeper grooves, balancing aesthetics with functionality.

3. Exposed Aggregate Finish

Exposed aggregate finish reveals the natural beauty of the stones and pebbles within the concrete mix by removing the top cement paste layer through washing, brushing, or acid etching. The result is a textured, slip-resistant surface with a decorative, high-end look often used for patios, pool surrounds, and public walkways. This finish is durable, low-maintenance, and allows for customization by selecting different aggregate types and sizes. However, it requires skilled labor and proper curing to prevent patchy exposure and ensure uniformity across the slab.

4. Salt Finish

The salt finish (also known as a rock salt finish) is created by broadcasting rock salt onto fresh concrete, then washing it away after the concrete sets. This technique produces shallow dimples and unique textures that enhance slip resistance and visual interest, making it suitable for driveways and patios. The salt acts as a spacer during the initial set, leaving behind small voids that can be tinted or sealed to highlight the pattern. While attractive and functional, salt finishes require careful timing and thorough rinsing to ensure consistent results.

5. Stamped Concrete Finish

Stamped concrete uses patterned stamps pressed into the wet concrete to mimic the appearance of natural stone, brick, tile, or wood. Color hardeners and release agents enhance the realism of the textures and create multi-tonal effects. This finish combines the strength and affordability of concrete with the aesthetic versatility of decorative materials, making it popular for patios, walkways, and interior floors. Proper installation is critical; the concrete must be at the right consistency, and stamps must be placed accurately to avoid uneven impressions.

6. Polished Concrete

Polished concrete achieves a high-gloss, mirror-like finish through a multi-step process of grinding, honing, and polishing with progressively finer diamond abrasives. Often combined with densifiers to harden the surface, this finish offers exceptional durability, low maintenance, and excellent light reflectivity, reducing the need for artificial lighting. Polished concrete is favored in retail, office, and residential interiors for its sleek, modern aesthetic. It requires a minimum concrete hardness of around 4,000 psi and skilled workmanship to ensure consistent sheen levels across the entire floor.

7. Acid-Stained Concrete

Acid staining involves applying acid-based chemical stains that react with concrete’s minerals to produce variegated, translucent color effects resembling marble or stone. Each floor develops a unique patina, making it ideal for decorative residential and commercial interiors. The process requires neutralizing and sealing to protect the finish and prevent uneven coloration. While acid-stained concrete offers rich, mottled hues and a semi-gloss surface, it can be sensitive to moisture and UV light if not properly sealed, so choosing the right sealer is crucial for long-term performance.

8. Epoxy Coating

Epoxy coatings consist of a two-component resin and hardener system applied over prepared concrete to form a durable, seamless surface. Available in a wide range of colors, including metallic and decorative flake options, epoxy floors offer chemical resistance, impact strength, and easy cleaning, making them preferred in garages, warehouses, and healthcare facilities. Proper surface preparation—typically through shot blasting or diamond grinding—is essential for adhesion. Epoxy floors can yellow under direct UV exposure, so UV-stable formulations or topcoats may be required for sunlit areas.

9. Decorative Stains and Dyes

Concrete dyes, unlike acid stains, are organic or water-based pigments that penetrate the surface to deliver vivid, consistent colors. Dyes can be mixed on-site to achieve custom hues and applied via sprayers or rollers for gradient or stencil effects. They are often followed by a clear sealer to protect against fading and abrasions. Decorative stains and dyes are best suited for indoor applications where UV exposure and moisture are controlled. They offer predictable, vibrant coloration but may require periodic re-sealing to maintain their appearance.

10. Overlays and Microtoppings

Concrete overlays and microtoppings are thin cement-based products (1–3 mm thick) applied to existing concrete to refresh worn or damaged surfaces. These materials can be troweled, stamped, or stenciled to create decorative finishes resembling stone, tile, or wood. Microtoppings are especially valued for their ability to hide imperfections and customize color, texture, and pattern. They adhere well when the substrate is properly prepared and moisture conditions are stable. While versatile, overlays require maintenance, as the overlay bond can weaken if subjected to heavy traffic without periodic sealing.

11. Self-Leveling Underlayment

Self-leveling underlayments are polymer-modified cementitious compounds poured over concrete to correct unevenness and create a smooth, flat surface ready for final flooring or polish. These materials flow easily, filling low spots and feathered edges, and set rapidly—often within a few hours—minimizing downtime. While primarily used as a preparatory step before other finishes, high-build self-levelers with decorative additives can serve as a final wear surface. Adequate priming and moisture control are crucial to prevent delamination and ensure long-term performance.

12. Cementitious Urethane

Cementitious urethane combines cement and urethane resins to create a thin, trowel-applied topping with excellent chemical, impact, and abrasion resistance. It is commonly used in industrial settings such as food processing plants, pharmaceutical facilities, and wastewater treatment areas, where hygiene and sanitation are critical. The material can withstand thermal cycling and is available in various colors. Proper mixing and application at the manufacturer’s recommended thickness—usually 2–3 mm—are essential for achieving full protective properties and adhesion to the substrate.

13. Colored Overlays

Colored overlays are thicker cementitious toppings (3–10 mm) enhanced with integral colorants to transform dull concrete into vibrant, durable surfaces. They can be troweled or textured, then finished with stamping, stenciling, or engraving to create patterns. Colored overlays are ideal for revitalizing outdated floors in retail, hospitality, and residential applications without full slab replacement. Their thicker profile offers better wear resistance than microtoppings, but they require meticulous surface prep and control joints to prevent cracking and ensure adhesion.

14. Textured Finishes

Textured finishes encompass a range of techniques—from combed and imprinted patterns to hand-troweled swirls—that create aesthetic visual effects and functional slip resistance. Patterns can be stamped, broomed in unique directions, or formed with specialty tools to mimic wood grain, slate, or custom designs. These finishes are popular for patios, pool decks, and commercial entryways where both style and safety are priorities. The choice of texture and pattern depends on the look desired and the intended use of the space.

15. Sealed Concrete

Sealers are clear or pigmented topical treatments that penetrate or film-form on the concrete surface to block moisture, stains, and wear. Penetrating sealers maintain a natural matte look, while acrylic or polyurethane sealers can provide gloss or satin sheens. Sealed concrete is easy to clean and maintain, making it suitable for residential and commercial interiors. Regular reapplication—typically every 1–3 years depending on traffic—is necessary to preserve protection and sheen levels.

16. Metallic Finishes

Metallic epoxy finishes incorporate metallic pigments into an epoxy resin base, producing swirling, three-dimensional patterns that catch and reflect light. These high-end, artful floors are popular in upscale showrooms, galleries, and modern homes. Application requires skilled installers to manipulate the pigments before the epoxy sets. While visually striking, metallic finishes can highlight surface imperfections, so meticulous prep and a smooth substrate are essential. A clear topcoat ensures durability and UV resistance to prevent yellowing.

17. Burnished Finish

Burnished (also called power-floated) finishes are achieved by using power trowels to compress the surface of a nearly cured slab, creating a smooth, low-luster sheen without additional coatings. Common in industrial warehouses and commercial spaces, burnished concrete offers improved abrasion resistance and dust control compared to basic trowel finishes. It requires timely application—troweling too early can weaken the surface, too late can prevent proper densification—so experienced operators are crucial for optimal results.

18. Brush Finish

A brush finish uses specialized brushes pulled across the concrete surface during the initial set to create fine grooves for traction. Unlike broom finishes, brush finishes employ tools with particular bristle stiffness or patterns to achieve decorative linear textures or herringbone effects. This finish is suitable for pool decks and outdoor walkways, offering a balance between aesthetic appeal and slip resistance. The choice of brush pattern can complement architectural styles or branding elements in commercial installations.

19. Shot Blasted Finish

Shot blasting is a mechanical surface preparation process where steel shot is propelled at high velocity to clean and profile concrete surfaces. As a finish, shot blasting exposes aggregate for a textured, matte appearance that enhances bonding for subsequent coatings or sealers. It’s commonly used in industrial floors, parking garages, and restoration projects to remove old coatings, adhesives, and contaminants while preparing the surface for new finishes. The resulting texture provides good slip resistance and a clean, uniform look.

20. Honed Finish

A honed finish delivers a smooth, matte surface with minimal reflection, achieved by stopping the polishing process at an intermediate grit (typically 400). Honed concrete offers a refined look without the high gloss of fully polished floors, making it popular for retail spaces, galleries, and residential interiors seeking understated elegance. It retains the durability and low maintenance of polished concrete but requires protective sealers to guard against stains. Honed finishes can highlight subtle aggregate patterns and color variations.

Conclusion:

Concrete floor finishes range from simple textured treatments to intricate decorative systems, each tailored to specific performance requirements and aesthetic goals. Understanding the characteristics, application methods, and maintenance needs of each finish ensures that designers, architects, and homeowners can select the optimal solution for durability, safety, and visual impact. Whether aiming for a sleek, polished showroom floor or a rugged, slip-resistant patio, today’s diverse concrete finishes unlock endless design possibilities while leveraging concrete’s inherent strengths.

Leave a Reply